Boat Building Academy Prospectus

April 2021

This is the current version of the Prospectus but please note there could be minor changes to Courses Starting after this date.

Covid-19

The Boat Building Academy is a registered educational institute and capable of teaching in all but the most restrictive Coronavirus situations. The practical nature of the course can be conducted with social distancing and they have implemented weekly lateral flow testing for Covid-19 for staff and students.

If the course is paused the course picks up again where it left off when allowed.

Download the Prospectus

Introduction

Tim Gedge founded the organisation in 1997. Boat building as an industry in the United Kingdom had declined and in some places had almost entirely disappeared. Where it did exist the end product was often mass produced. Boat building skills still existed among those with a lifetime of experience, but with the demise of the traditional apprenticeship there were few ways of ensuring that entrenched skills, learned over generations, were passed on.

All of the boat building and woodworking courses at the Academy are intensive and highly practical. At least 90% of students’ time is spent in practical activity in the workshop.

Academy students do not work on commercial projects: people learn a wider, deeper range of skills without the conflicts of interest that arise from the requirements of commercial work.

A wider range of boats are built by courses than are found in most boatyards, enabling students to gain practical experience of many different construction methods and techniques. Commercial work we are offered is passed on to our graduates.

In addition to gaining expertise in the practice and underpinning theory of boat building and allied fields some students also have the opportunity to build or restore their own boats as part of the 40 week ‘long’ course. Few places in the world offer this as part of an internationally recognised qualification. The value to all students is immense, the Academy offers an unparalleled depth and breadth of practical experience.

Some students use their time here and the advice of the instructors to develop an idea for starting a business. The use of these boats as training aids encourages analytical thinking and problem-solving skills beyond the usual boat building training norm. The flexibility and experience of the Instructors and the high instructor to student ratio means that students progress far beyond the level of a basic apprenticeship.

We aim for an instructor/student contact time of 40 hours per week and a staff/student ratio of 1:9.

Courses

• 40 week Boat Building, Maintenance and Support, the internationally recognised boat building course incorporating City & Guilds 2463 Level 3 Diploma in Marine Construction, Systems engineering and Maintenance.

• 12 week Furniture Making with a Level 3 Boat Building Academy Diploma (which is mapped and quality assured by PIABC). The course includes the design and construction of a personal project piece.

• 12 week Advanced Furniture Making. This course follows on from the 12 week Furniture Making course and is aimed at those who have reached Level 3 or similar, designed for aspiring professionals

and serious amateurs. There is no formal qualification, but the course gives professional guidance and support for those looking to work in the industry.

• Two to five day Short Courses covering specific skill areas; courses range from Introduction to Boat Building, Build a Boat – Initial Set-Up, Wooden Boat Restoration, Traditional Wooden Boat Building and Modern Wooden Boat Building, to Basic Woodworking and Furniture Making.

Students on all of our courses spend a minimum amount of time in the classroom. We feel it is vital to ‘do’, not talk about doing.

All of the courses are full-time and run from 0830 to 1730 five days a week. The workshops are also open in the evening and at weekends (subject to Health and Safety requirements being satisfied).

City & Guilds Level 3 2463

Boat Building, Maintenance and Support 40 week ‘long’ course

The flagship course that built our international reputation as a world-leading boat building training school.

There are two start dates per year: May and October in 2021, future years may be different.

We award a Boat Building Academy certificate in addition to City and Guilds certificates. The BBA Certificate is awarded to those on the course who have demonstrated a required level of commitment and achieved commensurate levels of capability and performance. The BBA Certificate is effectively a recommendation for employment.

The syllabus builds core competencies in boat building, with the emphasis on the practical. In broad outline the course timetable consists of:

Foundation – Woodworking Skills

We assume that everyone starts the course with no woodworking skills or experience.

During this intensive six-week phase students learn about different woodworking tools and how to use and sharpen them. The Academy lends each student a full set of tools and these remain with you throughout the course.

You are introduced to the vast range of timber types used in boat construction, including manufactured boards, learning about selection and preparation, common faults and defects. You will produce scarf, dovetail, widening and mortise and tenon joints, making practical pieces like a dovetailed box and a splay-head door.

Toward the end of this phase you have the opportunity to construct your own toolbox; an ideal place to store your own personal tool kit and a great way to demonstrate your skills.

Lofting

Lofting gives an understanding of the design process and a grasp of boat building fundamentals. Knowing how to loft from offsets (boat dimensions taken from fixed baselines) massively extends the range of boats a builder can choose from.

Students complete ‘teaching aid’ lofts and also loft the boats their group will build later in the course. If you can loft you can fair a hull and make adjustments for changing the type of hull construction from the original design (e.g. strip planking instead of clinker). You will also learn how to take the lines from an existing hull in order to replicate boats for which no plans exist.

Template Making

Students produce the moulds and templates that will be used in the construction of the course boats.

Using a variety of techniques for transferring shapes from lofting to pattern material, you will learn how to judge which mould materials are best suited to particular hull construction types, and how to make efficient use of materials. You will also look at the difference between temporary moulds and permanent frames.

Some of the moulds, via CAD, may be cut by CNC (computer numerical control) at Hooke Park, which acts as an introduction to the technology applied by the Architectural Association (AA).

- Splay head door completed in week 4

- Clinker section completed in week 5

Stitch and Glue Dinghy Build

An intensive week spent learning the basics of stitch and glue construction (also known as stitch and tape).

Each group builds a small dinghy from sheets of plywood and fits them out. The builds introduce some common boat building techniques like scribing, sheathing and the use of epoxy. For a nominal cost students can buy the dinghies they have built.

Jig Planking

Before being let loose on the ‘real thing’ you learn the basics of clinker, cold-moulding, strip and carvel planking on the boat building training jigs.

Laminated Stem

This is the first of two City & Guilds assessment pieces. You will loft the forward section of a small sailing dinghy, then take a template of the boat’s stem from the lofting, using that template to set up a laminating jig to produce a laminated dinghy stem. The assessment includes a short written test.

Fitting Out

During this phase you undertake a series of tasks from fitting rubbing strips, making centreboards, to

making floors or installing foredecks.

Oar and Spar

One week learning the art of oar making and the theory of spar making, discussing the variety of methods available to produce timber oars and spars, be they hollow or of stave construction. Make your own ‘bollow’ plane (a plane with a convex curve on two planes) to produce a spoon oar or alternatively make a canoe or kayak paddle or a set of flat bladed oars for your own boat. Later in the course masts and spars are produced for the course boats.

Sail Making

Design, cut shapes, machine and hand sew sails for anything from a small dinghy to a round the world yacht. Modern sail techniques are taught using a Sailrite sewing machine, hand stitching for emergency repairs and final finishing. The group may have the option to make a sail for one of the course boats (we draw straws).

Fibre Reinforced Plastics

Covering basic and more advanced (e.g. resin infusion) composite construction techniques.

Practise basic lay-up techniques for polyester resin. Discover the range of techniques available for producing simple plugs and moulds and learn the basics of plastic repairs, grinding angles and colour matching. At the end of the phase you will produce a 95cm model yacht, the second City & Guilds assignment.

Painting and Finishing

Different paint and varnishing systems; single and two-pack, traditional and modern.

Students learn how to prepare different surfaces for paint and varnish application and techniques. All of these techniques are used on course boats later in the training.

Wooden Boat Repairs & Restoration

We have a number of boats available for restoration work. Some students may also bring, by prior arrangement with the Principal, a restoration project as an ‘own boat’. Students survey a boat, producing a schedule of works.

They then learn how to maintain or restore the shape of a vessel, practise techniques for replacing planks, knees, deck beams and other items and get an overview of the problems that can occur on older boats. We also cover repairs to hulls constructed using glued techniques such as cold moulding and glued clinker.

Stern Tubes and Prop Shaft Boring

The techniques used for setting up engines and aligning and boring shafts. Learn how to install engine bearers on a variety of traditional and modern hulls and look at the variety of propulsion systems and stern gear options available.

Above decks fitting out

Methods of laying decks, traditional and modern, be they solid teak decks over traditional beams or a modern plywood sub deck with thinner planking glued or screwed down. Sessions on fitting deck beams, carlins and associated structures. Look at the variety of above deck structures; dog houses, wheel houses, coach houses and the types of fittings available, the methods for fitting them and appropriate reinforcements according to the deck construction.

Marine Systems

A week partly-run off-site at Rob Perry Marine, a marine engineering company ten minutes up the hill from the Academy. Hands-on experience of different engine types and principles, fuels and lubricants, exhaust systems, rigging and installation, electrics and corrosion. The week includes the RYA Diesel Engine certificated course.

Rope Work

Rope work techniques including three strand, double and single braids, making grommets, back, eye and other splices.

Build your Own Boat

Building boats as part of the course is integral to our training philosophy. The skills learned through this process can be taken into building, renovation, restoration and maintenance work

The number of boats we build is never more than half the number of students on a course.. We do not guarantee that everyone who wants to can build their own boat. Which boats are built is decided during the first three weeks of the course through discussion between students, instructors and the Principal. Boats built must satisfy the Boat Building Academy’s overall training criteria in that:

- They should be normally be no longer than 16 feet.

- They are of a construction type appropriate for the course, generally glued and traditional clinker, carvel, strip planked, cold moulded, composite, resin infused and stitch and tape.

- Students can also choose to restore a boat.

- The aim is to finish the boat by the end of the course (although there are very rare exceptions to this depending on the student’s objective in building that particular boat).

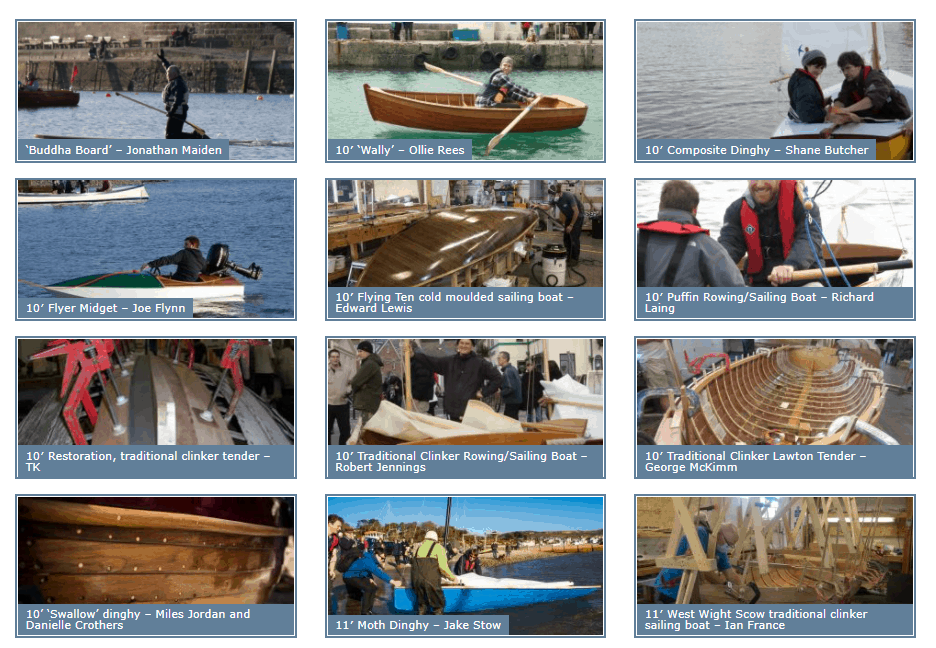

EXAMPLES OF OWN BOATS.

Student Boat Launches

At the end of each course the boats built by the course are walked in procession down to the sea and launched with due ceremony in Lyme Regis harbour. Guests are welcome to attend.

Outings

Southampton Boat Show

The Academy takes a day trip to the Southampton Boat Show each September. Entry to the exhibition and transport there and back are free to Academy students.

The show gives a good idea of the range of boats produced in the UK and abroad, from small traditional wooden boats to high-end, state-of-the-art timber composite boats, and from low-cost mass-produced plastic day sailers to multi-storey super-yachts.

Exhibitions

The Academy has a presence at numerous trade shows throughout the year; recent shows have included Countryfile Live at Blenheim Palace and Southampton Boat Show. At each show we exhibit boats and furniture built by students as part of their training. Have a look at our website to see which shows we will be attending over the year.

12 Week Furniture Making

Level 3 Diploma

Intensive and practical: the course includes skill building, a level 3 qualification and a personal project piece designed and made by the student. It includes 400 hours of scheduled bench time supervised by Instructor, Mark Ripley, a trained furniture designer/maker with over 30 years of professional experience. Visit www.mark-ripley.com for more information.

The workshops are accessible out of hours for students to continue working in their own time. The workshops include a bench shop with a cabinet making bench for each student, tool kit sufficient for completing the course and a separate dedicated machine shop which includes a range of small industrial quality floor standing machines and bench top machinery.

We visit workshops and galleries within an hour or so of Lyme Regis and a timber yard to buy wood for the project. Bi-weekly individual tutorials are held between you and the instructor where feedback is given in confidence.

The course features three distinct phases:

Skill Building

The first five weeks of the course focus on hand skills and power tool use. This includes sharpening, hand tool use, timber preparation and joint making. During this time the student will make a range of items including a bread board and dovetailed box with veneered top, hinges and a lock. During this phase of the course daily seminars are held on the theory of construction, timber technology, techniques such as steam bending and veneering and much more. Hand outs are given to support learning and The Woodworkers Manual, Jackson and Day is included in the fee as a study aid.

Level 3 Diploma

Weeks 6-9 are level three assignments undertaken by all students as training exercises. These are a small coffee table and a small Cherry and Maple cabinet with doors and a drawer. In addition you may take the optional Level 3 qualification. This is unique to the BBA and is externally assessed by PIABC. It includes 4 exams and 3 technical drawing assignments and is broadly equivalent to City and Guilds level 3 or an A level.

Personal Project Piece

During the final phase of the course students make a personal project piece. This will have been designed by the student in consultation with the instructor during the first 9 weeks. It will develop the skills learned so far and while the scope is broad it must be smaller than your bench top and be completed within three weeks. Typical projects include chairs, chests and coffee tables. Timber for the project is the only element of cost not included in the course fee.

12 Week Advanced Furniture Making

This course is for intermediate students wishing to develop existing skills to a professional standard. We ask that applicants can demonstrate that they have reached level 3 by bringing some work to the interview. The course takes the student through hand and machine skill development, cabinet making, fine drawer making and fitting, chair making, batch production and a personal project.

The course is run to simulate a commercial environment and has the same 8.30- 5.30 working day as all our courses giving around 400 hours of supervised workshop time. We aim to provide an environment for a steady pace of work and attention to detail, gradually building confidence and speed.

The facilities are the same as for the furniture making course but a greater degree of independence will be expected. Regular reviews will be held with the instructor to discuss assessments of set piece projects.

These will include:

• Small dovetailed box

• Footstool

• Console table with drawer

• Dining chair

• Wine table (group project in batch production)

Through this phase of the course weekly theory seminars will be held in:

• Techniques including producing complex curves, decorative joints, spindle turning and jig making

• Drawing, including an introduction to CAD

• Project design and development working towards the final piece

• Business studies relating to small commercial workshop operation

The final project is to be conceived as an exhibition piece. It will be no bigger than the work bench and aims to display a consistent approach to design and exacting craftsmanship. It will be developed through the initial phases of the course using sketches, models and mock-ups through to full-size drawings. It will also include project planning and costing.

Four weeks allows for a concentrated time to make a gallery standard piece. This together with your set pieces means you will leave with a portfolio of work.

Short Courses

Short courses run from 2 to 5 days. You do not need any prior knowledge of woodworking or boat building unless the individual course description states otherwise.

We are happy to discuss and plan a programme of short courses for you should you have a specific project in mind. If you book two or more courses there is a discount of 5%.

Use of tools and materials are included in the fee.

Boat Building Short Courses

• Introduction to Boat Building

• Wooden Boat Restoration

• Build a Boat – Initial Set-up

• Traditional Wooden Boat Building

• Modern Wooden Boat Building

• GRP Repairs

• Renovation and Finishing

• Rope Work

• Sail Making

Woodworking Short Courses

• Introduction to Woodworking

• Woodworking Skills 1-4

• Bench Making

• Marquetry

• Antique Furniture Restoration

• Bench Making

Please ask for further information and costs on the short courses if you are interested.

Accommodation

The Boat Building Academy has limited on-site accommodation that is available to students. There are twelve single study bedrooms, a large fully equipped kitchen, dining room/sitting room with wood burning stove and shower rooms, and a further sitting room.

Accommodation, subject to availability, is offered to all students on courses at the Boat Building Academy.

Should the accommodation be full, we will, within reason, help people joining longer courses to find a suitable place to stay in Lyme Regis or the surrounding area through our network of local people.

Our housekeeper, Wendy, looks after the communal areas of the accommodation. Residents are responsible for cleaning their own rooms (clean bed linen is provided) and for cooking and washing up, although home -cooked breakfast and lunch are usually available at a minimal cost on most weekdays.

There are coin operated washing machines, a tumble drier, iron and ironing board and each resident is given fridge, freezer and larder space. There is wireless broadband access in most parts of the building.

Rooms are reserved on a ‘first come, first served’ basis as people book their places on a course, although we do try to give priority to students on the 40 week Boat Building course.

Tea break on the beach Students

How to apply

Interview

We do not believe that a requirement for formal qualifications or any form of test are helpful in assessing whether candidates will complete a course successfully. We look for a mature attitude, motivation and a clear enthusiasm and willingness to pursue the highest standards. Application and dedication to the course are key.

All potential ‘Long Course’ and ‘Fine Woodworking’ students are asked to attend for interview and bring a simple CV. You will be taken on a tour of the Academy, giving you the opportunity to visit the workshops, see what work is being produced and what boats built, in addition to meeting students on the courses and seeing the accommodation.

You will then discuss with the Principal why you want to join the course, what you hope to achieve on it, and what you hope to do with your skills at the end of the course.

Finally you will discuss with the Principal any further questions that your visit may have raised.

The interview process is constructed to give you a feel for the work and life of the Academy, so that you can make a decision about whether this form of intensive and highly practical training is appropriate for you. If you are a suitable candidate for the training you will be offered a place.

If you cannot attend for interview

If for any reason you cannot attend for interview we ask you to send us your CV. If we feel you are a suitable candidate we will contact you and ask you to make an appointment for a telephone interview. On the prearranged date either the Principal or the Training manager will conduct an interview. If, on the basis of that interview, we feel the course is appropriate for you we will offer you a place on the course and send you a booking form.

Taking your place

Once you have been offered a place you are free to join any future course as long as there are places available.

Course Prices correct at 02-01-2021 and are subject to change.

40 week Boat Building, Maintenance and Support

The fee for the 2020 courses is £15,850. Included in the fee are materials, including those for a glass reinforced plastic boat, clinker section, laminated stem, bollow plane, joints and a 7ft oar that you make during the foundation phase of the course. These are yours to take home. The only extras are for the materials of items you choose to take away with you; a toolbox, another oar and (last but not least) a boat. We receive good discounts from our suppliers and discounts are given to you.

12 week Furniture Making/Advanced

The fee for the 12 week Furniture Making course is £5,850 plus the cost of the materials for your personal project piece.

The fee for the 12 week Advanced Furniture Making course is to be confirmed, so please contact the

office for further information. Likewise with the 12 week Furniture Making course, the fee does not include cost of materials for the personal project piece.

Students benefit from the good discounts we receive from our suppliers. All pieces you produce other than the personal project piece are included in the fee.

Payment

If you are offered a place on a longer course we ask for a 20% deposit for the 40 week Boat Building course and a 10% deposit to reserve a place on the 12 week Furniture Making courses, with the balance paid one month prior to the start of your course. Please do not give us a deposit until you are ready to commit to a course. Short course fees are paid in full when reserving a place.

Should you need advice on access to funding please contact the Administration Office.

Accommodation

Long course students intending to stay for 40 weeks £100.00 per week

Fine Woodworking students intending to stay for 12 weeks £100.00 per week

Those on short courses £35.00 per night

Students on the 40 week Boat Building, Maintenance and Support and 12 week Fine Woodworking courses are invoiced for accommodation one month in arrears.

Included in the course price

The course fees for the 40 week Boat Building, Maintenance and Support course and the 12 week Fine Woodworking course include:

• All City and Guilds and PIABC registrations

• Use of tools

• Materials – (excluding boat/furniture projects)

• Tea, coffee and biscuits a.m. and p.m.

• Personal Protective equipment

• Visit to Southampton Boat Show (boat builders).

• Stationery

Questions

Adam and Debbie have both attended the Clinker Boat Repair Course and Debbie is doing the 40 Week Boat Building Course.

If you have any questions please ask us.

Classic Sailing 01326 53 1234

.

Download the Prospectus