The Captain writes

Grayhound Ongoing Work

Grayhound is continuously being serviced and maintained. Despite being a brand new wooden ship there are still plenty to do to keep her in the great shape she is. Once a year we do a 1-2 months of intense re-fit. Usually this happens each spring before the season starts and in time for our yearly inspection. Part of this is done during the yearly haul-out when we put on fresh anti-fouling.

Natural materials

We have an on-going project to reduce the amount of no-natural materials and paints used on the ship. We try to replace as much as we can with proper pine tar, linseed oil, hemp etc as well as not use tropical wood whenever we can. We have for example stopped using Bitumen paint on all the blocks and removed it from the bulwark and over water part of the hull. We are also removing all plastic based paint and replacing it with linseed oil based paints.

Just some of the work we have done so far includes:

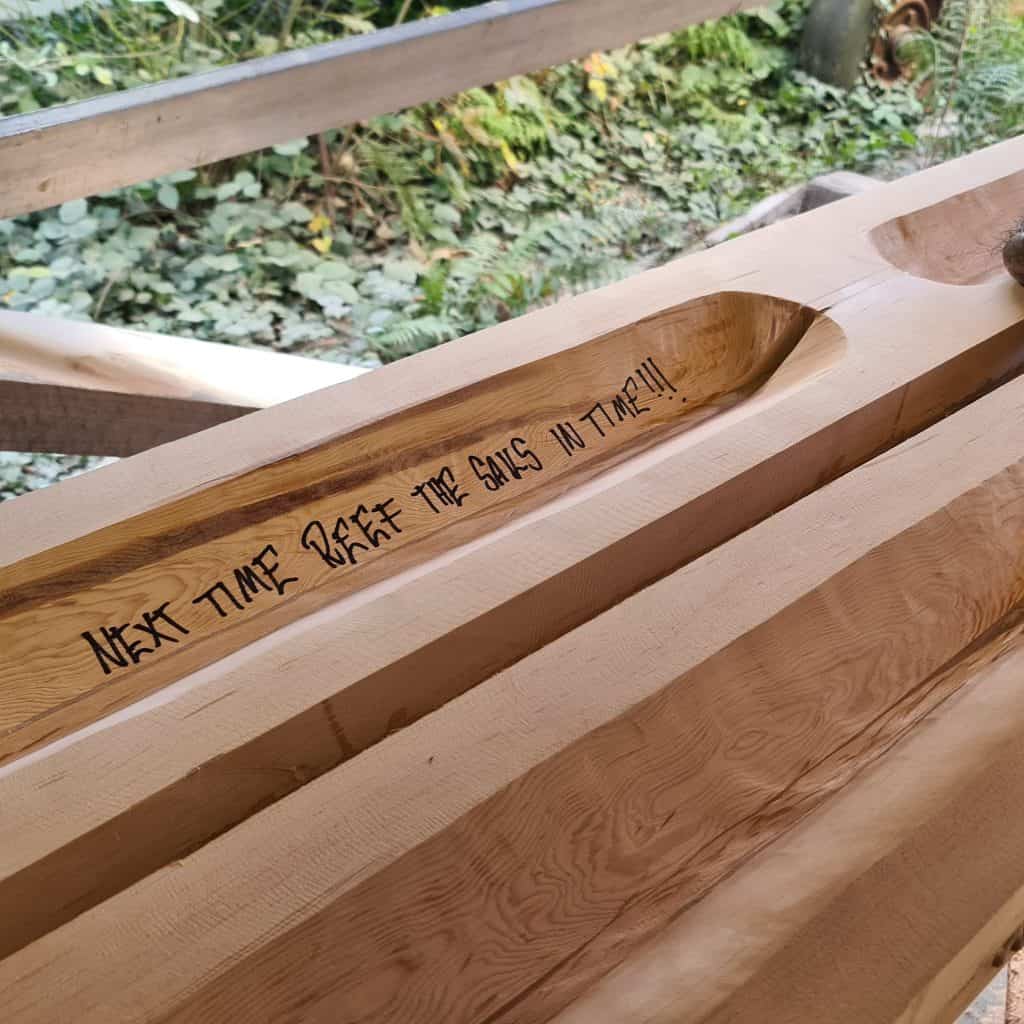

– building a new fore mast yard from Oregon Pine. We made it hollow to bring down the weight.

– We have taken down all blocks on the ship, taken them apart, removed all bitumen paint, serviced, renovated, replaced and then soaked them all in a tar and linseed oil mixed bath for weeks before putting them back together again.

– Rebuilt and improved the lounge area in the galley and changed the wood stove.

– Rebuilt the entire saloon with new bunks and a new dinner table.

– Changed all the interior lights in the ship to more nautical looking lights with a softer light.

– We have scraped and removed bitumen paint from the bulwarks and painted with a mix we call the “Roslagsmahogany” (one third raw linseed oil, one third Swedish tar and one third balsamic turpentine). This work will continue down the over-water part of the hull. But here we will also add a natural colouring additive called ‘Kimrök” in Swedish (Carbon black in english). Smooth actually.

– We are now in the process of replacing all the shrouds and adding deadeyes that we make ourselves from the European grown wood Black Locust. The wires are treated traditionally with tallow, cotton drenched in a tar mix, served with tarred hemp rope and then seized loops with seizing wire.

– we will also service our gigs, sails and other wear and tear on the ship.

An on-going never-ending but fun work.

Wille Christiani

Shipowner and CEO